Shipping Containers Poised to Solve COVID-19 Hospital Housing Shortage

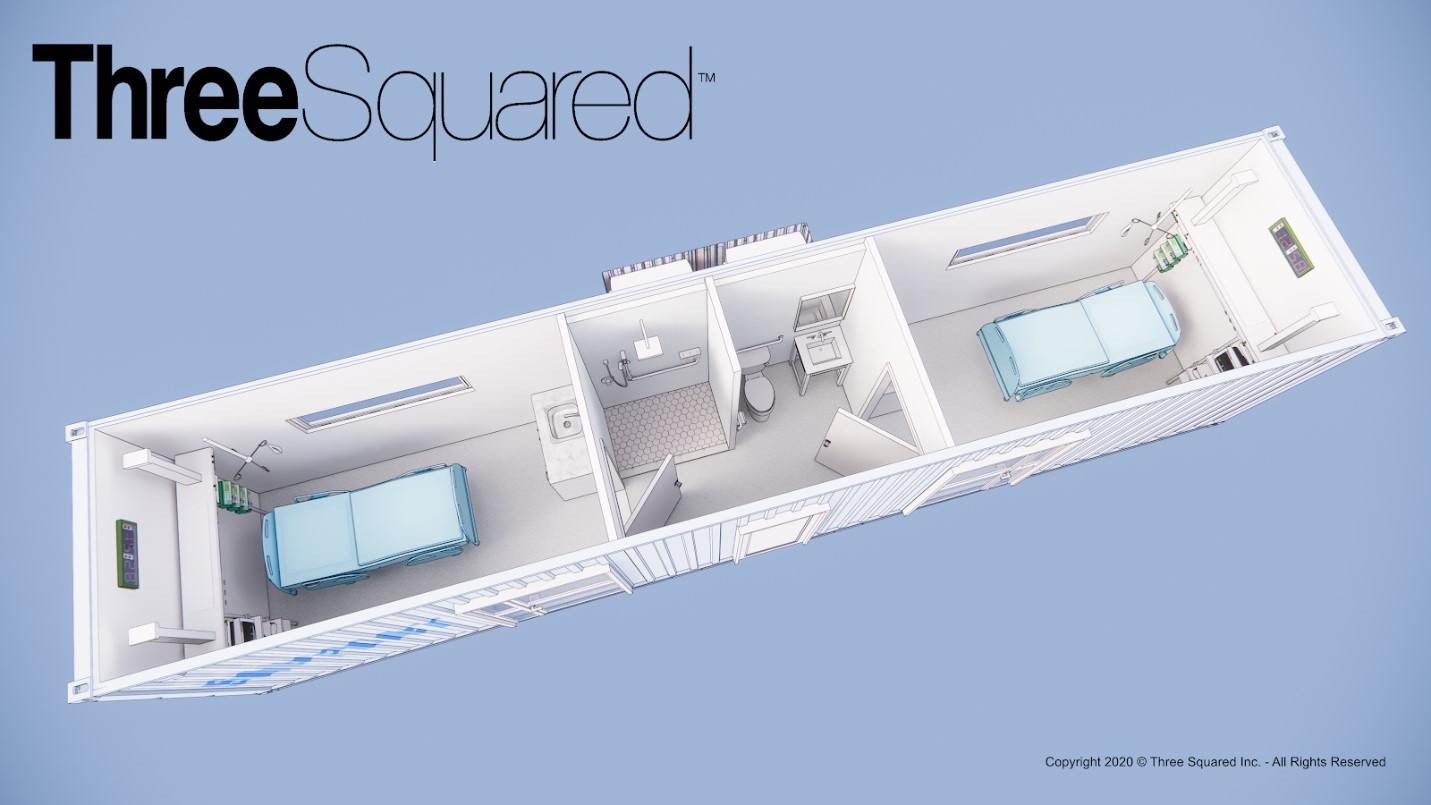

::: To efficiently and effectively resolve hospital bed and hospital staff housing deficits nationwide, cargo architecture firm Three Squared designs two custom-outfitted mobile shipping container units—one housing multiple hospital beds for patients, another for housing attending medical staff—complete with electrical and full bathrooms :::

Photo Copyright Three Squared Inc.

Amid throngs of daily reports lamenting the critical lack of hospital beds and similar space shortage concerns for morgues in the wake of COVID-19, with makeshift tents being erected on both fronts as a short-term “BAND-AID,” one company has been think-tanking what could be a hugely viable solution for all. Detroit-based cargo architecture firm Three Squared, whose steel cargo containers are typically used for innovative multifamily and mixed-use housing applications, is now proffering its state-of-the-art cargo container dwellings not only as relief units for hospital and morgue/mortuary overflow, but also as appropriately-appointed and climate-controlled housing units for doctors and nurses needing to stay close to those patients.

“Amid the crisis, we’ve been refocusing our residential lodging efforts to instead resolve the current hospital housing crisis,” notes Leslie Horn, CEO of Three Squared. “In consultation with several doctors who’ve shared front-line problems and needs in relation, and through concerted efforts to rally and align with other builders in the shipping container sector, we’ve identified two distinct gaps in hospital housing and successfully devised two specialized solutions to wholly resolve these needs.”

According to Horn, Three Squared’s first solution would provide direct and immediate relief for those hospitals facing a bed shortage. Specifically, a mobile cargo unit that is delivered via truck, hooked up to temporary plumbing and power, set on temporary foundations, and covered with a temporary tent structure. Each unit contains two hospital beds, also with a central bathroom with running water. The bathroom also has an exterior door so that doctors and nurses can decontaminate before leaving the unit at any time—a feature suggested by one of the consulting doctors.

Another doctor Three Squared consulted with voiced concern around the shortage of temporary housing for doctors and nurses who need to so stay close by patients while also maintaining necessary social distancing protocols. Thus, the company’s second proposed solution involves shipping container units set up in a similar fashion for use as the hospital staff relief—temporary housing for medical staff located near the patient hospital bed cargo units.

“After the pandemic has run its course and the hospital patient and staff-use shipping container structures have achieved their objectives, the cargo units will be picked back up and delivered to a final ‘afterlife’ resting place as housing for homeless, veterans, disaster relief, college dormitories, food growing operations and more. They can also be easily stacked and stand ‘at-the-ready’ to assist in future disaster relief efforts,” Horn notes.

States from coast to coast are facing the reality of hospital and morgue space shortages. As these facilitates scramble to increase capacity, even employing options that present a myriad of downsides and even added challenges, Horn asserts that it’s imperative for the solution to this issue be one that not only can be deployed quickly, but also effectively for however long it needs to be utilized.

“Three Squared’s extensive knowledge and experience in building with standard ISO shipping containers allows us to pivot our focus from affordable multifamily housing structures to fill this immediate medical need, promptly and most efficaciously,” Horn said. “Our particularized craft of architecture has the ability to expedite the construction process and get temporary and even permanent buildings to high need areas in less than half the time as conventional methods. This speed is key for meeting these demands and is one of the key advantages of cargo architecture.”

Not only that, Horn also indicated that the company has devised a streamlined process from design, budgeting and bidding, all the way through fabrication and delivery. With current operations, its team reportedly has the capability to acquire, modify and deliver two shipping container units per week—also with the highly scalable option to ramp up production to meet increased needs, as necessary.

Horn also underscored that, as a company, Three Squared continues to seek feedback and opportunity for collaboration to assist those tirelessly working to care for patients and manage the current COVID-19 healthcare crisis. “We understand that buildings of any scale are the product of no one person, but rather the efforts of many people working together to create the best possible functionality,” she said. “Our staff is devoted to being good stewards and use our residential housing skills, knowledge and experience to do anything we can to help support healthcare workers during these unprecedented times.”

Given Three Squared’s sustainable and eco-friendly housing units are billed as being “faster, stronger and more energy efficient”—and considering the specialized adaptations mentioned above—this cargo architecture company just might have devised the definitive quick fix to stave off this seemingly imminent disaster.

~~~

Sources:

***Some or all of the accommodations(s), experience(s), item(s) and/or service(s) detailed above may have been provided at no cost and/or arranged to accommodate this review, but all opinions expressed are entirely those of Merilee Kern and have not been influenced in any way as per the disclosure policy on our “Legal” page***